Diisopropylamine in Chemical Industry

Welcome to Servochem LLC. The worldwide chemicals sector depends upon specially crafted intermediates that offer reliable performance, limited reaction rates and steady processes. In recent years, Diisopropylamine-DIPA has started to be an important chemical in this area owing to the way its molecules are arranged, which lets its reactions stay fairly consistent. With other industries asking for better results and stronger quality checking, Diisopropylamine is growing in manufacturing fields.

Servochem LLC with over 40+ years of experience writes an article that kind of clarifies how Diisopropylamine in Chemical Industry works and it gives a focus to what is chemical identity and also how it is used in the industry. The text covers value for commerce as well importance for those B2B companies from packaging, automobile textile and construction.

What Is Diisopropylamine-DIPA?

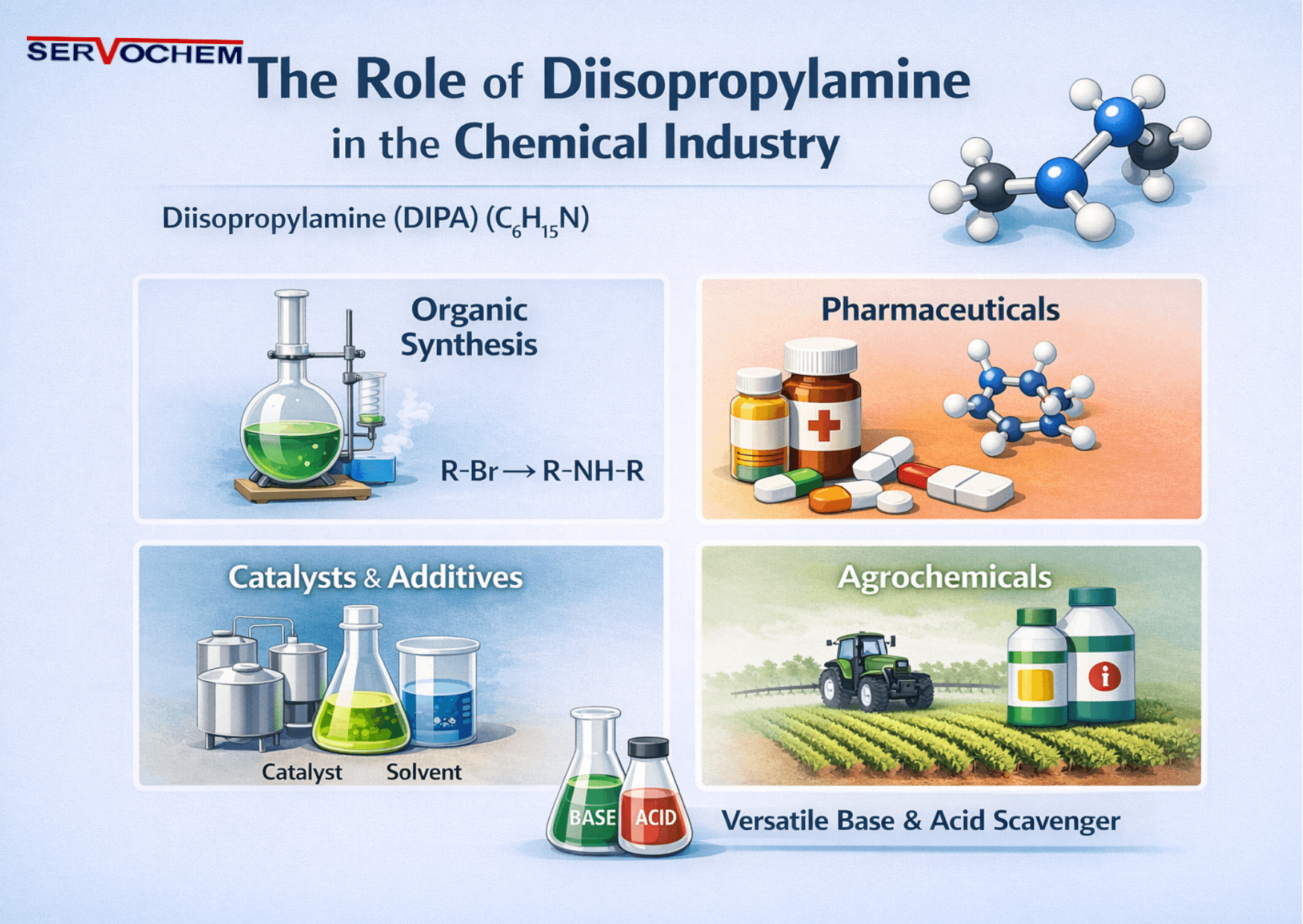

Diisopropylamine, also called DIPA by most, is known as secondary aliphatic amine, and it is mostly used as an intermediate chemical for supporting processes which is seen very often in different industrial syntheses. Unlike amines which react easily, DIPA is valued because it interacts in a controlled way in the chemical environments, so workers in factories can reach more expected output.

In industrial environments, DIPA is used where:

- You need specific reactions to happen

- Maintaining stability in mixtures is necessary

- Mass production that demands things to be always the same

Its purpose is basically more supportive than central, making it required in places where reliability and keeping things stable is much more needed than fast reacting.

Chemical Structure and Molecular Characteristics of DIPA

How DIPA acts in chemical factories is much about the molecule shape. If you look into the diisopropylamine structure, you will notice why it is reliable in a lot of situations in the industry.

Structural Overview

- Nitrogen binds with two isopropyl groups.

- It has a secondary amine type group

- There is branching in the molecule, which causes some steric blocking

Because of this build, there is control over random chemical reactions, but it can take part efficiently in various production uses.

Key Molecular Identifiers

- Diisopropylamine CAS No.: This number is for making rules compliance, keeping safety files, and monitoring materials.

- Diisopropylamine molecular weight: Helps match solvent uses and watching the reactivity

These details matter to buyers quality officers and also to regulatory teams in chemical use and handling.

Diisopropylamine in Chemical Industry Why it is Important

DIPA is an important compound for chemical companies because its main function is to help in process control not to cause heavy chemical conversions. That is especially useful for the B2B factories where if you keep the operation steady, you get more money.

Key Industrial Benefits

- Better efficiency for productions

- Fewer items rejected

- Less time lost and less restarting old jobs

For manufacturers, these benefits translate into:

- Higher production efficiency

- Lower rejection rates

- Reduced downtime and reprocessing

Because chemical factories do more exact production, DIPA is an essential part of getting the same result.

How to Choose High-Quality Diisopropylamine (DIPA)

Servochem LLC is giving out three big things that need to be considered by manufacturers when looking for a DIPA for different chemical industries. By looking at these points, it helps to lower mixing risks, stay inside regulations and makes the production work smoother.

- Correct Grade Selection

- Purity and Chemical Profile

- Reliable Supplier and Documentation

Getting the right type of DIPA provides stable reaction rates and a more similar performance in industrial applications; however, the wrong type can lower the output and the effectiveness goes down. Diisopropylamine at high quality is having purity controlled, low water and almost no extra substances so the reaction is stable and batches are similar.If supplier is trusted, quality does not change, the packaging is right and documents are there for keeping rules and no production gets stopped.

Commercial Considerations and Supply Factors

When buying DIPA for business, it involves other concerns than only price. Producers consider if a product remains trustworthy, it sticks to its specific specifications, and stays true to its technical paperwork as well.

Main Commercial Checking Features

- Purity is supposed to be regular and also the specifications are to stay as expected.

- Packaging for use in factories should be safe.

- There must be complete documentation to support the product facts.

Because market demand is now shifting into multiple areas like packaging, assembling of cars and building materials, being in a longer supplier relationship is important. DIPA review at Servochem LLC lets producers check on supply and good quality.

Strategic Importance of DIPA for B2B Manufacturers

Diisopropylamine helps not only with usual tasks but in chemical factories, it is kind of an important part for an easy and large-scale manufacturing.

Long-Term Value Proposition

- Provides stable production possibilities

- Helpful for improving process steps and scaling up things

- Lowers instability in complicated formulations

When B2B manufacturers work in the packaging, automotive, textile or construction industries, DIPA can be a trusted ingredient making sure the business targets and daily operations can be matched for the future.

Diisopropylamine: Frequently Asked Questions (FAQs)

Why is diisopropylamine considered a critical intermediate in the chemical industry?

Diisopropylamine plays a critical role in the chemical industry because it enables controlled and selective reactions during complex synthesis processes. Its steric structure helps manufacturers reduce side reactions, improve product purity, and maintain consistency in large-scale production, making it highly valuable for pharmaceuticals, agrochemicals, polymers, and specialty chemical manufacturing supported by Servochem LLC.

How does diisopropylamine add commercial value for downstream manufacturers?

Diisopropylamine adds commercial value by improving process efficiency, lowering reprocessing costs, and enhancing batch reliability across industrial applications. For downstream manufacturers in sectors such as automotive, packaging, textiles, and construction, its use supports stable formulations, predictable performance, and better long-term cost control when sourced from experienced suppliers like Servochem LLC.

Supplying Diisopropylamine to countries

we Export Diisopropylamine to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, Israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, Europe, Africa, Asia, North America, South America, Middle East, Far East Etc.

Servochem LLC, is a well known worldwide exporter of Chemical products, is committed to providing each and every customer with the highest standard of customer service. We deal in Diisopropylamine worldwide, offering a wide range of chemical products.

Similar post: Diisopropylamine vs Triethylamine: Key Differences

Internal Links: Diisopropylamine-DIPA

External Links: Diisopropylamine