Diisopropylamine is generally more suitable for large-scale industrial manufacturing because it provides better batch consistency, safer handling, and reduced impurity formation. These advantages are especially important for automotive, packaging, textile, and construction material manufacturers seeking predictable performance and cost efficiency when sourcing through Servochem LLC.

Diisopropylamine Vs Triethylamine

Welcome to Servochem LLC. In procurement of industrial chemicals, the choice for a suitable amine is not really just something you do in the lab, but it becomes a decision with the business focus. Two widely discussed chemicals, diisopropylamine vs triethylamine, are often used throughout chemical making, polymers, material processing and pharmaceutical industries.

Despite looking like they could be switched for one another, there are remarkable changes in molecular actions, different costs and how they behave in products later. Manufacturers in sectors like automotive, textiles, packaging and construction will find these changes have an influence on production optimizing, regularity in products and steady supplies.

Servochem LLC with over 40+ years of experience wrote the industry-centered article for people making decisions not for those in academia.

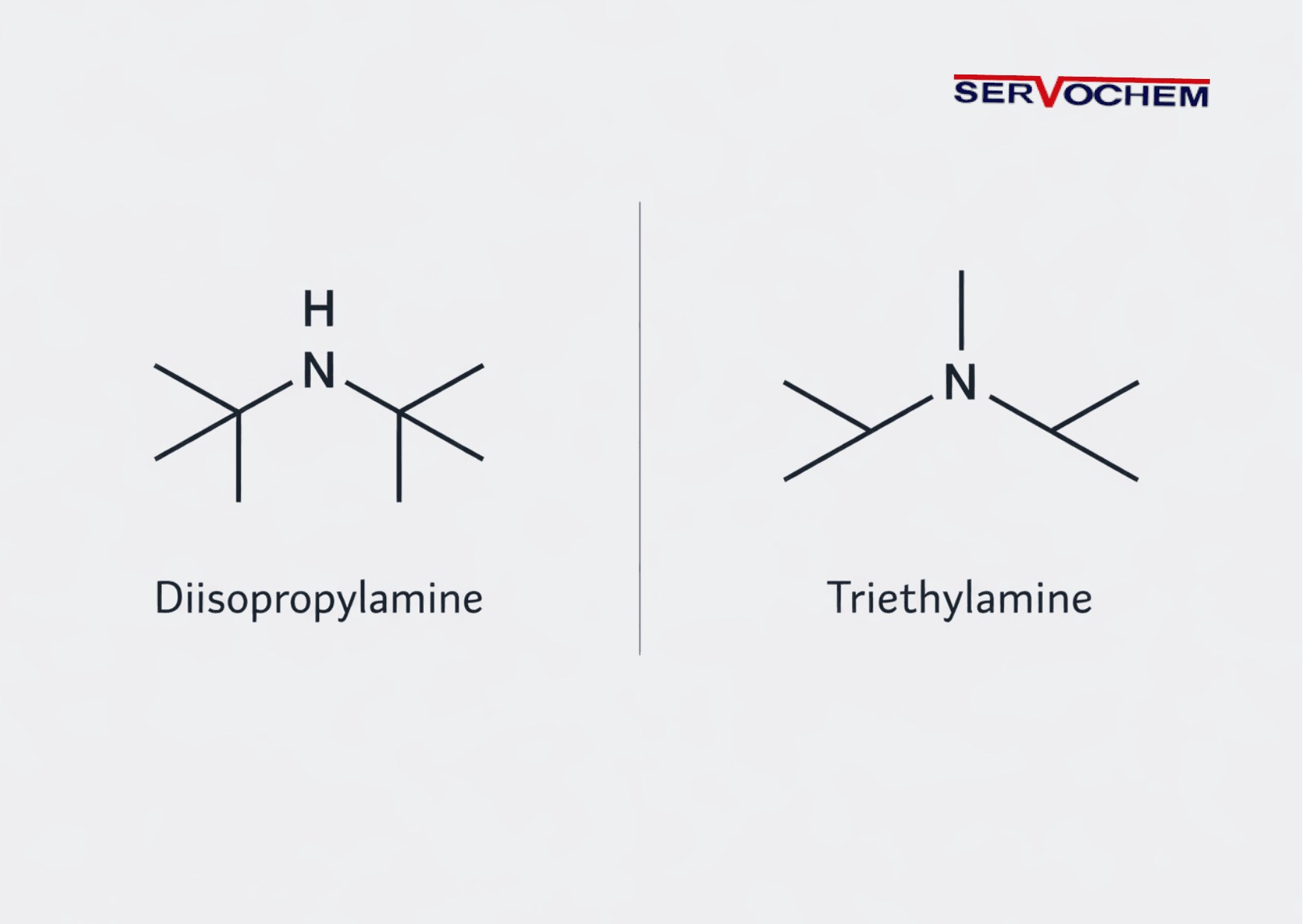

Chemical Identity and Structural Differences of Diisopropylamine vs Triethylamine

Diisopropylamine vs Triethylamine

The key difference between diisopropylamine vs triethylamine starts at their molecules. These both can be called an aliphatic amine, but the way the structure is put together determines how they will act in actual production jobs.

Diisopropylamine (DIPA)

This is a secondary amine and it comes with the larger isopropyl groups. Its heavy steric hindrance stops it from doing reactions too much. DIPA is famous for the pathway control of the reactions. It is usually called with its mass as diisopropylamine mw when planning the formulas.

Triethylamine (TEA)

This amine is a tertiary with smaller groups of ethyl. Reactions go faster by their higher nucleophilicity. It is also much more aggressive and volatile.TEA is often used in situations needing quick neutralizing.

So, for B2B uses, these things change how you keep reactions in check, affect impurity forms and make scaling up commercial batches possibly more reliable. It’s kind of important you understand those differences for better results in the jobs ahead.

Reaction Behavior and Process Control in Manufacturing

If comparing diisopropylamine with triethylamine, the way their reactions behave is an important point. At the level of industrial manufacturing, what is needed is reactions that can be predicted mostly, more than just doing it quickly.

How Diisopropylamine Performs

Diisopropylamine or DIPA gets chosen for its slower and steadier reactivity rate. Because of its big structure it gives less chance for extra reactions that are not wanted, it is good for synthesis steps where perfect results are more important than getting there fast.

Operational advantages include:

- Selectivity when doing chemical processes is higher,

- Risk for producing unwanted secondary products drops down,

- Batches show more constant results from time to time,

- and continuous production lines become more proper for use

How Triethylamine Performs

Triethylamine works at a faster rate and reacts more strong. This sometimes is helpful for simpler neutralization reactions but it often gives problems with complicated mixtures.

Operational trade-offs include:

- You get finished reactions quicker.

- Due to higher volatility stricter methods for handling must be enforced

- Chance of forming impurities increases

- Safety and air flow demands go up

When working in industries that care about regulations, cutting down the waste and regular production quality, tight control of the reactions usually is chosen instead of just going for faster processing.

Industrial Applications Across B2B Sectors

Servochem LLC gives three important downstream application zones that help manufacturers work with diisopropylamine with triethylamine in a better way. Learning how these chemicals act not just at synthesis but in actual production and during time products are used helps to prevent risks in mixing as well as helps in better working control and makes sure industry production is regular.

- Packaging and Polymer Manufacturing

- Automotive and Construction Materials

- Textiles and Specialty Chemicals

Diisopropylamine (DIPA) is used in keeping polymer changes managed and cures resins for packaging since its low volatility allows coatings to stay stable while producing lots at once. In the area of car and construction items, DIPA helps to carefully make adhesives and sealants, keeping how they work even when facing heat and stress, while the Triethylamine, which is more volatile, may cause troubles in processing. In textile and special chemical manufacturing, DIPA makes finishing results more consistent and cuts down on rejected products, so manufacturers who want stable results and close controls often pick this option.

Commercial Considerations: Pricing, Handling, and Supply Stability

Looking at buying options, the comparison between diisopropylamine and triethylamine becomes about the cost and also how to manage movement and security.

Triethylamine Commercial Price Factors

- Most often it is cheaper at a first

- More wastage happens because it is volatile

- Raises safety spending, and also costs more to store

- There sometimes are legal compliance expenses

Diisopropylamine Commercial Value

- Has an aggressive price in moderate operations

- Not so much product disappears in handling

- Waste after use and need for reprocessing is kind of minimized

- Gives improved long run cost benefits.

Even though triethylamine seems cheap in the beginning, it is observed by market buyers that diisopropylamine can prove better for full ownership cost over a longer period.

Safety, Storage, and Operational Risk Management

Industrial purchasers should think about safety features alongside the operational risks when picking a diisopropylamine or an triethylamine.

Diisopropylamine shows less vapor pressure so it can be stored and kept contained easier. Odor is much lower and exposure is not so high in workplaces. This makes compliance tasks simpler for most of industry operations.

Triethylamine, which is more volatile and comes with a strong smell, needs more developed air systems. There are greater chances for losing the material and handling these chemicals becomes more difficult.

Lowering operational risks in bigger facilities means protection of the workforce and saving costs.

Strategic Procurement and Supplier Selection

Getting suitable amine depends not just on chemistry, but also on what a supplier can do, steadiness, and support given with technical needs. People who make diisopropylamine DIPA usually focus on the suppliers that know about industrial demands and not just general product shipping.

Strategic sourcing considerations include:

- Reliable quality and keeping of records

- Supply that can rise with bigger production needs,

- The right technical expertise for end-user industries

- Pricing that stays steady and also planning how deliveries occur

Servochem LLC assists the manufacturers in B2B with chemical options that kind of look at industrial goals, not mere quick buying.

Choosing the Right Amine for Long-Term Industrial Success

When you compare triethylamine and diisopropylamine, it mainly depends on how well they fit with targets of production. Triethylamine is used for reactions that are quick and easy. But diisopropylamine is chosen when the need is for an expandable system of production, controlled, or is required to meet the regulations.

Packaging, automotive, textiles and construction industries needing steady quality and stable function start to prefer diisopropylamine for the strategic use. Industrial environments where safety, efficiency and exactness matter, using the correct chemical brings benefits for the future, not only for right now. Sometimes, like, the choice may seem kind of subtle but it impacts outcomes big. Also, you should consider if there are environmental factors to think about. Besides, the regulations of industry may require specific conditions and amine types depending on those.

On the weekend, companies sometimes review the chemical components used to upgrade processes or comply with new directives. Choosing the amine that fits well with production goals plays an important role in ensuring the success of your operation and staying ahead of competition.

Diisopropylamine Vs Triethylamine: Frequently Asked Questions (FAQs)

What is the main industrial difference between diisopropylamine and triethylamine?

The main industrial difference lies in reaction control and handling behavior. Diisopropylamine offers slower, more controlled reactivity with lower volatility, making it suitable for precision manufacturing and large-scale processes, while triethylamine is more reactive and volatile, often used for faster neutralization steps. B2B manufacturers working with Servochem LLC typically choose based on process stability and long-term operational efficiency.

Which compound is more suitable for large-scale industrial manufacturing?

Supplying Diisopropylamine to countries

We Export Diisopropylamine to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, Israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, Europe, Africa, Asia, North America, South America, Middle East, Far East Etc.

Servochem LLC, is a well known worldwide exporter of Chemical products, is committed to providing each and every customer with the highest standard of customer service. We deal in Diisopropylamine worldwide, offering a wide range of chemical products.

Similar post: What Is Diisopropylamine Used For? Key Industrial Applications

Internal Links: Diisopropylamine-DIPA

External Links: Diisopropylamine