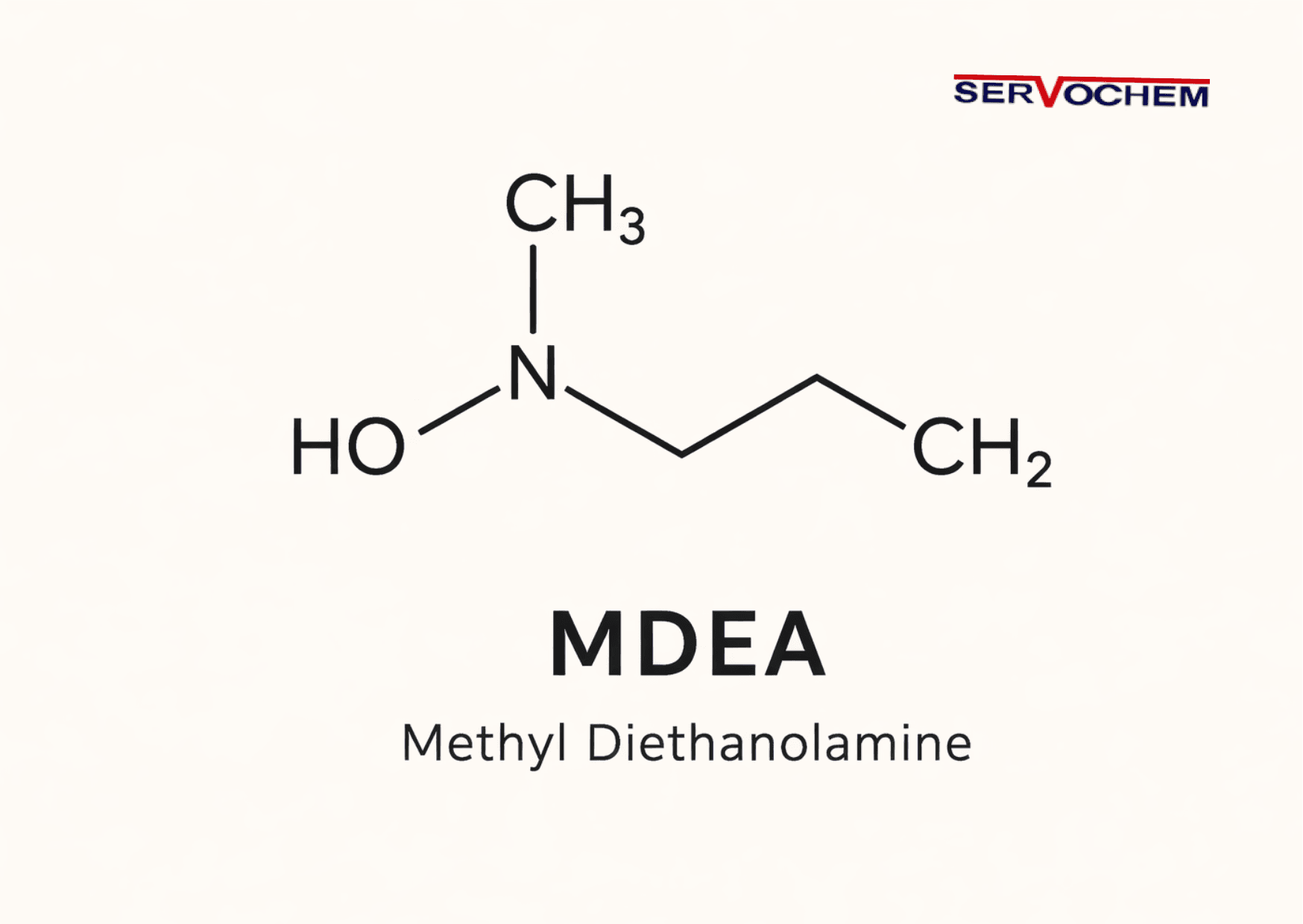

Methyl Diethanolamine MDEA

Welcome to Servochem LLC. In recent times, chemical buying choices are not only based on prices or whether supplies are available. Industrial procurement teams now try to look at how steady the performance is, if the supply chain can be trusted, and whether regulations are followed closely, and whether the material will work with the processes in the long run. Inside this situation, Methyl Diethanolamine or MDEA turns into an important chemical for many of the downstream manufacturing sectors.

As spaces like textiles, construction, automotive, and packaging get more focused on efficiency improvements and improving their process methods, specialty amines such as an MDEA are starting to be used outside of regular areas. For best mdea manufacturers selling to other businesses, it is important to see how this chemical functions inside production steps, so that the product’s quality stays high, the risk of operations reduces, and scaling up is possible.

Servochem LLC, with over 40+ years of experience, aims to provide support to individuals involved in industrial decision-making, such as those in purchasing and those who conduct assessments to determine commercial and technical value, ultimately driving change in the manufacturing world.

What Is Methyl Diethanolamine in Industrial Contexts

Methyl diethanolamine belongs to set of organic compounds that are called an alkanolamines. The molecule includes both an alcohol group mixed with an amine group leading to having two types of functions at once. This kind of structure causes it to become helpful as an intermediate for chemical reactions and a substance for neutralizing and sometimes it can serve as an stabilizer where it is needed in the formulas.

Do you know? How It Differs From Other Alkanolamines? When you look at monoalkanolamine or dialkanolamine, methyl diethanolamine has a reaction pattern that is balanced. It does not act too strongly or too mildly. This trait is helpful for those processes needing managed chemical exchanges.

Key differentiators include:

- Lower degree of volatility even with a high processing heat;

- Better stability for formulas that need to last during the storage;

- Less possible chemical side reactions.

For these reasons, downstream factories pick methyl diethanolamine for the products that are meant to stay useful for longer time periods instead of short usage phases.

Benefits or Importance for Businesses

Operational Advantages for B2B Manufacturers

When it comes to industrial buyers, how useful MDEA chemical is goes beyond just chemistry in the lab. It gets its actual value during big scale usage, especially on production lines with outcomes finishing as goods.

Primary business-level benefits include:

- Process Efficiency: It helps make reactions flow easier, which means batches become less different between each other

- Quality Uniformity: Production can stay steady for even very big manufacturing processes.

- Cost Optimization: Can cut down on needing redoing and also there is less change in the formulation as time continues

- Supply Chain Stability: Because it is common to many global chemical requirements, it is steady for the supply chain.

Sector-Specific Business Impact

Packaging Manufacturers

- Allows the coating to stay more regular

- Makes the adhesives last and laminates more stable

Automotive Component Producers

- Makes some resin items stronger against use

- Is good at stopping a rust-making formulas

Textile Processing Units

- Helps fiber treatment to be more constant

- Makes less difference for finishing chemicals

Construction Material Manufacturers

- Adds to more steady cures

- Performance of additives can be guessed better

For companies with many products, such flexible methyldiethanolamine uses means not needing as many special chemicals which makes buying easier.

Common Challenges or Mistakes

Inconsistent Grade Selection

Industrial purchasers usually encounter troubles in getting material grades that do not give stable purity or have no consistent composition monitoring. Small changes at molecule scale can cause remarkable differences in how things perform further down the production line.

Supplier Fragmentation

Depending on various suppliers or dealers brings issues such as:

- The quality of batches is irregular

- Documents sometimes missing

- Spikes in demand cause slow deliveries

Limited Technical Alignment

It often happens some may say choosing suppliers is decided without full cooperation with people from formulation or those who handle production. This gap results in chemicals that satisfy the business requirements but they do not really work for operational conditions.It can cause delays and product failures.

To get around such problems, buyers need companies that merge the ability to produce, technical skills and supply chain resources. Like, this kind of integration helps smooth functioning of the entire process.

How Servochem LLC Helps Simplify This

Integrated Manufacturing and Supply Capability

Servochem LLC is a company that works for industrial chemical buyers who want everything all together. Instead of small suppliers, Servochem makes several kinds of water-treatment chemicals in its own factories and also has a bigger stock of regular chemicals and petrochemicals inside M.E.N.A. region.

This integrated model ensures:

- Reliability in quality between batches

- Better control of how products meet requirements

- More rapid answer for changing volumes

B2B-Centric Value Proposition

For those who produce materials further, Servochem LLC gives more than only products.

- Technical matching with industrial needs

- Delivery logistics can grow for domestic and outside customers

- Compliance documents always ready for industries, needing them

If manufacturers buy from one expert source they reduce problems in their work and get better procurement dependability in the future.

Quick Steps to Get Started

Companies that want to use MDEA chemical in their manufacturing present or an future can follow an easy onboarding process, set up on purpose to avoid complexity:

- Tell your needs and how much you need per year.

- Afterwards you have a commercial or technical alignment talk.

- You are able to ask for the specifications and samples to review.

- Finish deal for supply terms and how it will be delivered.

This organized plan can give both investment and performance protection through ensuring compatibility. This kind of plan provides protection for investment and also for performance.

Methyl Diethanolamine MDEA: Frequently Asked Questions (FAQs)

Why should buyers source Methyl Diethanolamine (MDEA) from Servochem LLC?

Servochem LLC is a trusted supplier of Methyl Diethanolamine (MDEA), catering to global industrial requirements with a strong focus on quality consistency, regulatory compliance, and supply reliability. The company offers MDEA suitable for critical applications such as gas sweetening, refinery processes, surfactant manufacturing, and specialty chemical formulations.

Key reasons buyers choose Servochem LLC include:

Strict quality control aligned with international chemical standards

Reliable bulk supply and export-oriented logistics

Technical support for application-specific MDEA grades

Competitive pricing for long-term industrial procurement

This combination makes Servochem LLC a preferred partner for industries requiring dependable and scalable MDEA sourcing.

What industries does Servochem LLC serve with its MDEA supply?

Servochem LLC supplies Methyl Diethanolamine (MDEA) to a wide range of downstream industries where purity, performance, and process compatibility are critical. Major industries served include:

Oil & Gas – for acid gas removal and gas treating units

Petrochemicals & Refineries – as an amine solution component

Chemical Manufacturing – intermediates and formulations

Surfactants & Personal Care – pH adjustment and stabilizing roles

Industrial Processing Units – specialty and customized applications

By supporting multiple industrial verticals, Servochem LLC ensures that its MDEA meets diverse operational, regulatory, and performance requirements across global markets.

Supplying Methyl Diethanolamine MDEA to countries

We Export Methyl Diethanolamine MDEA to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, Israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, Europe, Africa, Asia, North America, South America, Middle East, Far East Etc.

Servochem LLC, is a well known worldwide exporter of Chemical products, is committed to providing each and every customer with the highest standard of customer service. We deal in Methyl Diethanolamine MDEA worldwide, offering a wide range of chemical products.

Internal Links: Methyl Diethanolamine MDEA

External Links: Methyldiethanolamine