What Is Diethylene Glycol and Why Is It Used?

In 2025, there is a rising need for industrial intermediates while manufacturers expand by using new materials, technologies and increasing scales of production. A chemical substance, Diethylene Glycol (DEG), is now an big factor in the expansion. Fields like resin manufacturing, polyester fibers, lubricants, construction chemicals, coolant applications and glue systems use materials for keeping product cycle stable. Often producers will ask themselves what is the Diethylene Glycol, and what causes it to be useful for lots of industrial procedures.This comes from its flexible structure with consistency when used for different things.

When we talk about Servochem LLC so we have more than 40+ years of experience in the petrochemical industry. We are known as a chemical manufacturer and supplier worldwide; additionally, we are popular for our faster transportation chain with a 30-day delivery. We specialise in Diethylene Glycol chemical, it’s suitable for the Textile and PET Industry.

What Is Diethylene Glycol (DEG)?

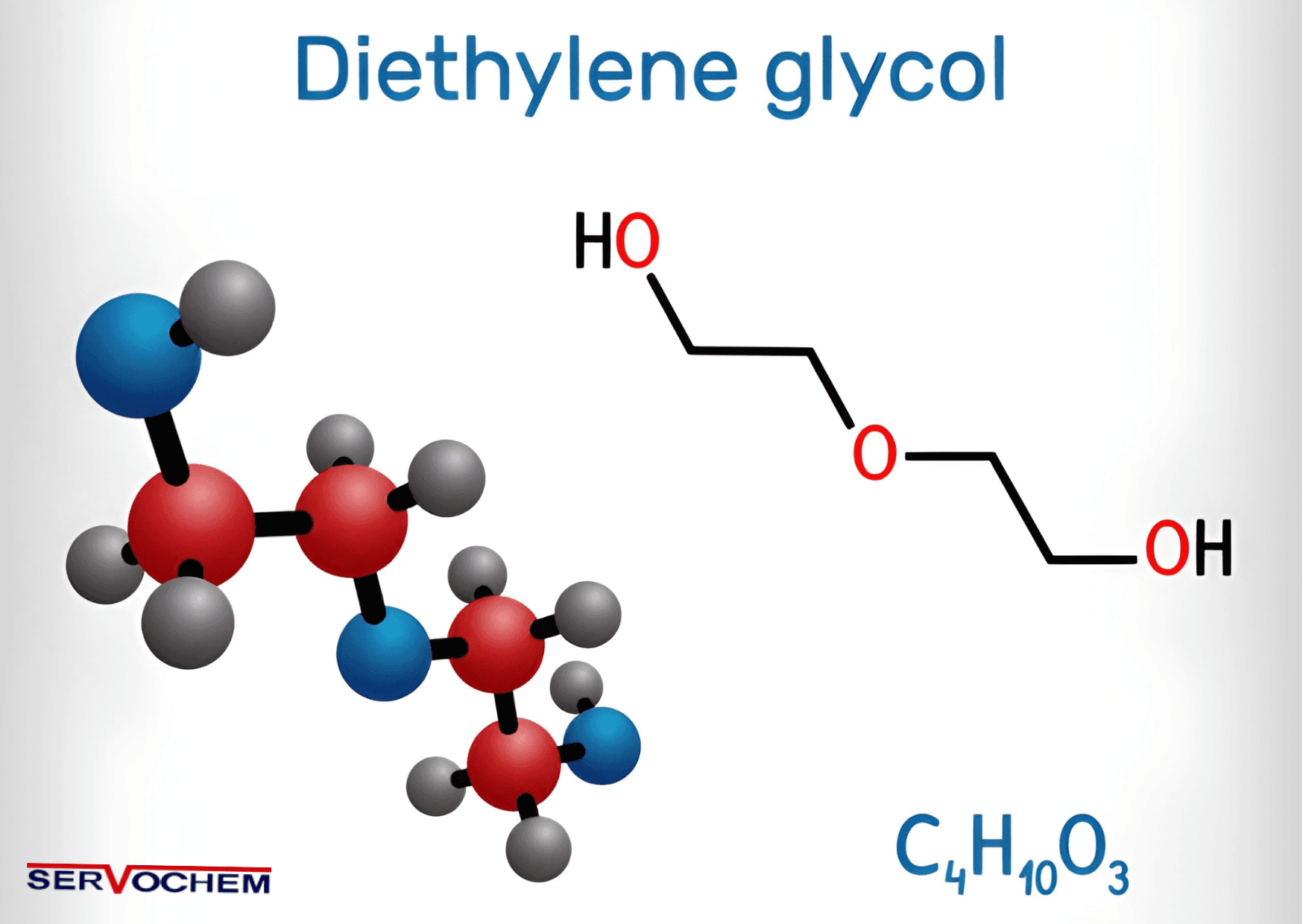

Diethylene Glycol looks clear and not very thick, and it can take in water from around, being hygroscopic, with a chemical sign as C4H10O3. Globally people call it the cas 111 46 6, so this chemical fits when companies need to trade and fill the paperwork for industry use. Many businesses want to know the things that make the DEG separate versus other usual solvents. This mainly is because of having two parts of ethylene glycol in the molecule, joined together using an ether bond, which changes the way DEG acts. The compound gets a higher boiling spot, dissolves more smoothly, and acts regularly when the temperatures keep changing.

It is popular since it dissolves in many liquids and stays stable so it is used in moisture reduction, keeping the things flowing well, and acting as a dissolver. In industry, DEG helps by making the products more uniform and preventing weird changes when mixing or heating. So it fits for making polyester, mixing coolant liquids, sticking agents and a number of other industrial routines.

Expanding Industrial Use of DEG Chemical

The larger adoption of Diethylene Glycol during year 2025 shows like the way that industries are changing. Manufacturers are putting forward the questions about a reason DEG is becoming more significant and response lies in the increasing number of fields that use trustworthy intermediates.

Some main drivers are:

- Demand for polyester fibers and resins is rising.

- Automotive growth leading to a need for different kinds of brake fluids or coolant mixtures.

- Construction sectors need more stable solvents that can be used in putting or coatings

- More attention worldwide to having traceable, as well as compliant raw materials

- Ongoing uptick in export-focusing industries that must have the verified intermediates.

Servochem LLC is still providing help to industries by giving reliable Diethylene Glycol shipments.They keep making sure material quality stays regular for buyers worldwide and locally.

Industrial Applications of Diethylene Glycol

1. Textile and Polyester Processing

DEG is very important in area of polyester and textile making, where it is mainly used to make a polyester resin and fiber products. Many of the people who work in this sector wonder why DEG always enhances polyester quality. This is because DEG puts smoothness, makes polyester flexible and creates better clarity. Its presence helps dye to get distributed equally in finishing stage, supports resin merging when forming, and also makes fiber production more steady.

2. Automotive Coolants and Brake Fluids

DEG is a chemical also needed in car coolant liquids, hydraulic machinery, and brake fluid for vehicles. Having a stable viscosity, high temperature resistance and good compatibility with chemical additives is helpful for keeping temperature balance in engines and proper fluid working. DEG gets used in car factories because it gives corrosion protection as well as keeping the fluid reliable even when temperature changes suddenly happen.

3. Coatings, Resins, and Industrial Chemicals

With producing resin and coating, manufacturers ask about keeping film smooth and surfaces steady. DEG improves this by mixing solvents better and making the mixture even. When making construction materials, paint for industries, filler and glue substances, DEG is used for applying consistency and enhancing finish result.

4. Solvent Systems and Chemical Intermediates

DEG serves as a transporter, reaction element, and constant solvent in varied chemical formulations. Those who produce adhesives inks and cosmetic goods use DEG to ensure texture feels correct viscosity remains stable and the shelf durability is long time. The ability of DEG for mixing with different organic items is the reason it becomes most favoured solvent in manufacturing locations.

Chemical Identity and CAS Registration: CAS 111 46 6

Every industrial chemical receives special CAS number that makes it easier for buyers to check product and follow it in different documents. Diethylene Glycol is recognized by the cas 111 46 6, which helps companies worldwide accept and identify it. Companies that do an exports or deal with several chemical grades gain as tracking with CAS makes procurement and storage less complicated and inspection of quality easier.This identification is useful for buyers so they get right material, which helps keep production areas safe.

Quality, Packaging, and Industrial Grades

Many customers want to know how the DEG purity changes way production goes. The response is, purity affects how steady things are, and that steadiness makes end product quality better. Servochem LLC makes sure every DEG supply passes proper industry regulations.

Main specifics about our supply:

- We have a purity more than 99.5 percent

- CAS 111 46 6 material checked

- We pack into drums at 230 kg or IBC tanks and also bulk tankers

- Industrial suitability for textiles is there and also for the chemical blends, resins or different polymers

- We use storage that controls contamination or moisture

- All reliable documentation such as MSDS and TDS are included

This way, manufacturers get materials which match their operation needs and batch issues are less. I kind of hope this helps.

Importance of Reliable DEG Supply in B2B Production

Manufacturing plants in textile, packaging, construction and automotive industries need a continuous input supplies so they keep their operations moving.Whenever firms wait longer for the DEG deliveries, this can impact their batch processing, cycles and also the blending precision. Servochem provides help through the services like: Export and inland logistics; supply cycles which are predictable; purchase amounts with an flexibility; support on technical topics using documentation; and skilled distribution channels. This way, the producers keep more steady production downtime goes down, and vendor schedules are satisfied.

Sustainability and Demand in Modern Manufacturing

There is movement in the chemical sector to be more sustainable, and an DEG production too is now changing for new environment rules. Distillation operation is improved, emissions cut and waste control upgraded, making supply chain less dirty. Servochem LLC partners with those factories who manufacture by the environmental rules, so industries get materials that meet modern sustainability instructions. Sometimes, you know, the changes are subtle but important. The focus on better processes and reduced emissions helps not just planet but also kind of the reputation of businesses. It is interesting how sectors shift according to pressures from regulation and market demands. Supply chains become cleaner and efficiency gets better.I think this trend will continue strongly in near future.

What Is Diethylene Glycol and Why Is It Used? : Frequently Asked Questions (FAQs)

What makes Diethylene Glycol suitable for industrial formulations?

Diethylene Glycol is preferred because it offers stable viscosity, dependable solvency, and consistent behavior in high-temperature or moisture-sensitive environments. These properties help manufacturers maintain uniformity across processes such as resin creation, coolant blending, and textile finishing.

Is DEG safe to use in automotive or chemical applications?

Yes, DEG is widely used in automotive fluids, chemical intermediates, and industrial blends when handled and stored according to standard guidelines. Manufacturers follow proper documentation, including TDS and MSDS, to ensure correct usage, compatibility, and workplace safety.

Supplying Diethylene Glycol to countries

We Export Diethylene Glycol to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, Israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, Europe, Africa, Asia, North America, South America, Middle East, Far East Etc.

Servochem LLC, is a well known worldwide exporter of Chemical products, is committed to providing each and every customer with the highest standard of customer service. We deal in Diethylene Glycol worldwide, offering a wide range of chemical products.

Similar post: Diethylene glycol supply in India

Internal Links: Diethylene Glycol

External Links: Structure of DEG and related polyols